What is electric motor and how it is made?

An electric motor is a device that converts electrical energy into mechanical energy, which is transmitted through an electromagnetic field. The first electric motors appeared in the early 19th century, but it took quite some time before they saw widespread use. By the end of the 19th century, however, they had already entered commercial application. At first, motors powered by direct current (DC) were introduced, soon followed by those running on alternating current (AC).

Today, both DC and AC motors are in use. DC motors are often found in mobile applications such as cars, trucks, and bicycles, while AC motors are more common in devices that can be connected directly to the electrical grid. Besides the type of current, electric motors can also be classified as synchronous or asynchronous.

The supply voltage can vary greatly as well. Some motors operate on as little as 12 volts or even less, while standard supply voltages include 110V or 230V (common household outlets in many countries), or 400V in our case (a three-phase outlet). There are also motors that run on high voltages of several thousand volts. These are just some of the ways in which electric motors can be categorized.

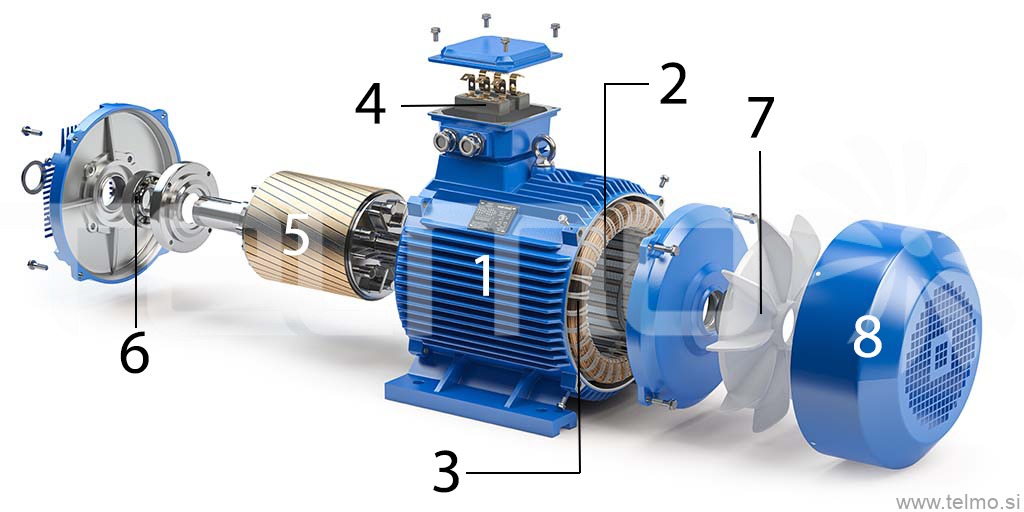

Among the most widely used are asynchronous motors powered by alternating current, which are typically either single-phase or three-phase. An example of a three-phase motor is shown in Figure 1.

Composition of a three-phase asynchronous electric motor:

- The housing of an electric motor is a fundamental component of the motor. It usually consists of a main central section and side covers, into which the bearings are inserted. The rotor—the moving part of the motor—is then mounted into these bearings. Motor housings are typically made from aluminum or cast iron alloys. The exterior of the central section is often ribbed, which helps the motor dissipate heat generated by energy losses.

- The stator is placed inside the central part of the motor housing and is made of laminated steel. These laminations contain longitudinal slots that hold the most important component of any electric motor—the electrical windings. Viewed together with the motor housing (Fig. 1), the stator also contains the largest amount of material relative to its weight.

- The electrical windings can vary significantly from one electric motor to another. They typically determine the number of revolutions the motor will make. Windings can be made from different conductive materials in wires of various diameters, with copper and aluminum being the most common. In addition to the conductive material, the windings contain various insulating materials.

- To ensure that a motor operates reliably for many hours, the quality of the materials used is crucial. Higher temperature-rated insulation materials, the type of varnish used to insulate the wire, the thickness of the varnish coating, and similar factors can all contribute significantly to the motor’s durability and performance.

- The terminal plate with a junction box, where the motor’s power supply is connected.

- The rotor of an electric motor is the rotating (dynamic) part of the motor. Through the rotor, energy is transmitted to the device’s user. This transfer can occur in various ways, such as via a chain, belt, gear, or similar mechanisms.

- Bearings are an important part of an electric motor, as the motor’s lifespan largely depends on them. Among all types, single-row ball bearings are the most commonly used.

- The cooling fan of an electric motor is mounted on the rotor shaft and ensures that the motor does not overheat.

- The protective cover of the fan prevents it from deforming and ensures it is safe for the user. At the same time, it directs airflow over the motor’s cooling fins, helping to minimize overheating.